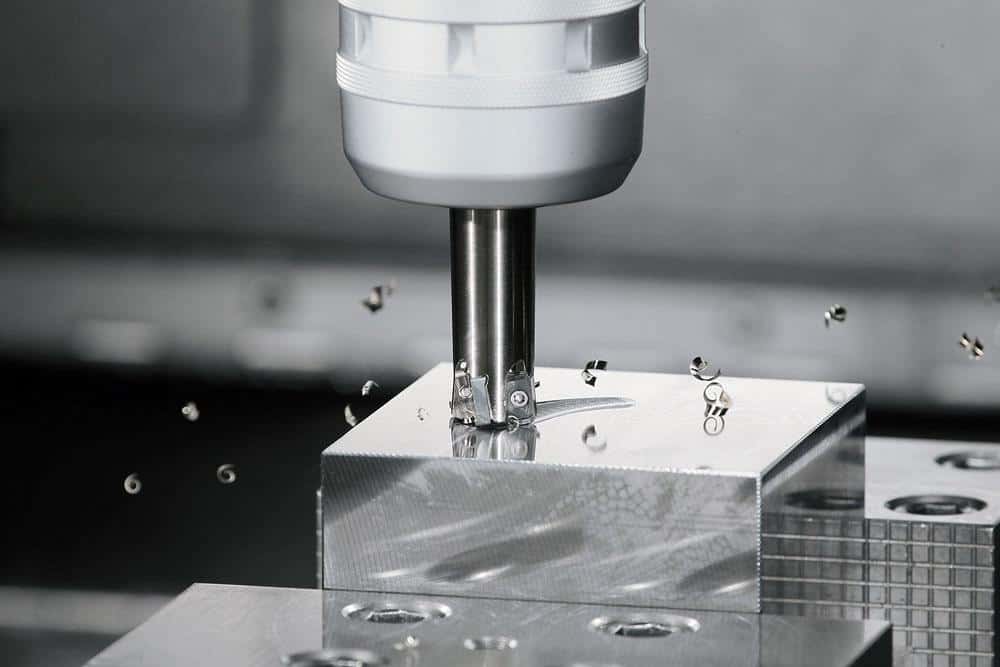

Carbide tooling solutions and companies that use their products have a significant advantage working with the rigid material of Carbide for their business needs. Epic Tool is based in Stoney Creek, Ontario, and works exclusively with carbide. We proudly produce upwards of 300 custom carbide tools a day and manufacture everything on our Canadian soil! […]

Read More… from Using Custom Carbide Tools to Create a More Competitive Business