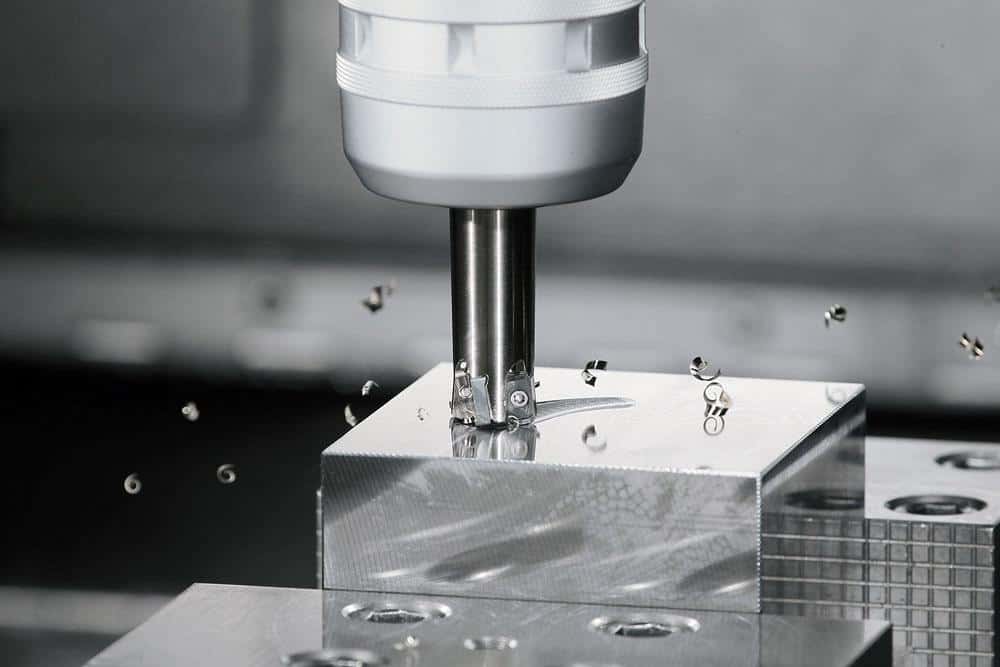

The implementation of CNC (computer numerical control) technology has dramatically transformed the manufacturing industry, providing a highly efficient and cost-effective means of producing a diverse range of products. However, with the increasing need for intricate and complex products, advanced CNC techniques have become increasingly popular. These innovative techniques include multi-axis machining, 3D printing, Direct Energy […]

Advanced CNC Techniques in 2023