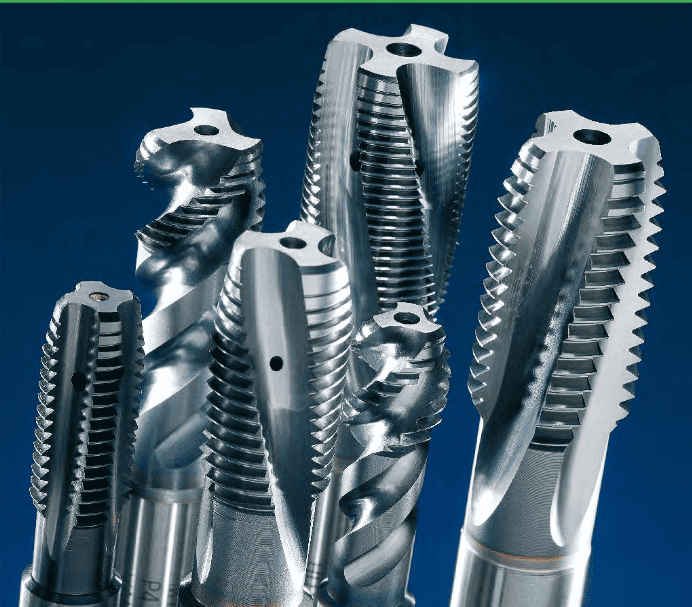

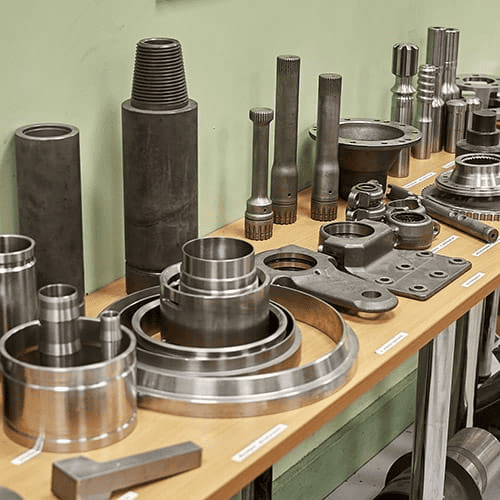

Manufacturers worldwide are now focusing on sustainability in the rapidly evolving industrial landscape. Companies are increasingly concerned about climate change and environmental impact and seek innovative ways to reduce their carbon footprint and promote eco-friendly practices. YAMAWA is a leading provider of cutting-edge tapping tooling solutions that are revolutionizing the manufacturing industry while advocating for […]

Sustainable Manufacturing: YMW Revolution