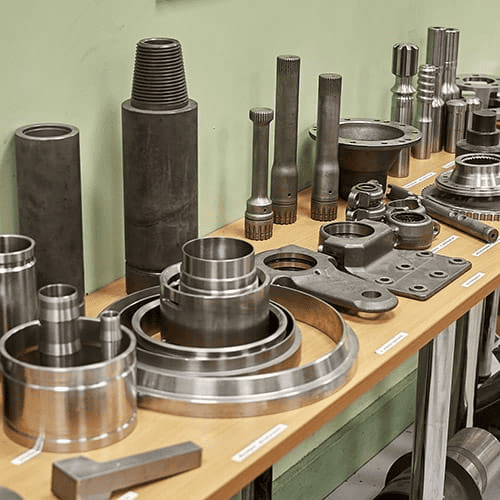

In the intricate manufacturing world, precision and efficiency are paramount, especially in the realm of die and mold production. Epic Tool, a stalwart in the industry since its establishment in 2005, has been a key player in providing essential tooling solutions for the Mold and Die making sector. Let’s delve into the die and mold […]

Read More… from Navigating Mold and Die Making with Epic Tool