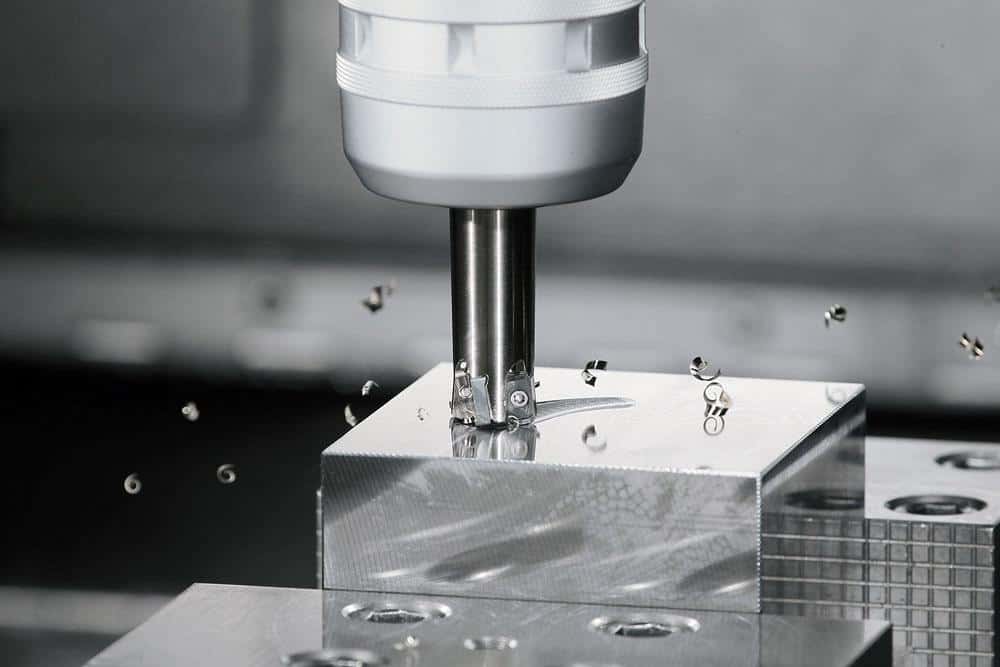

Solid carbide drills are essential tools for many machining processes, as they can easily cut through tough materials like steel, cast iron, and titanium. These drills are highly efficient, durable, and precise, making them a popular choice for various applications. There are multiple configurations and geometries of solid carbide drills, each designed to suit different […]

Read More… from What are the different types of solid carbide drills?