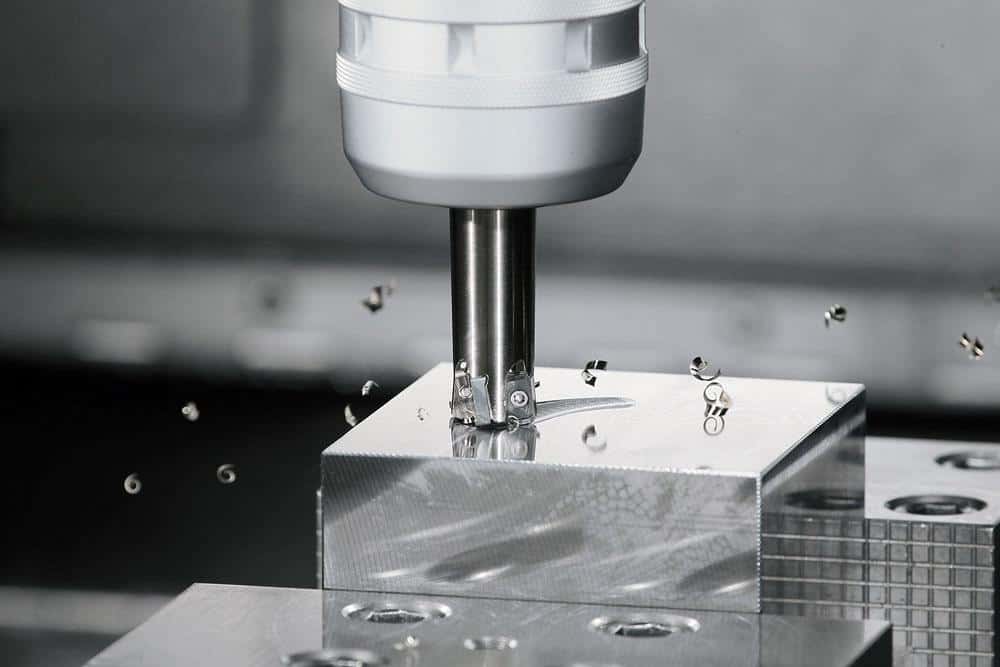

Computer control milling is the process of cutting various tools and materials and is one of the most popular methods of production for major industries and manufacturers. This method produces very specific and intricate cuts, which is why endless major industries use CNC milling. The team here at Epic Tools specializes in manufacturing custom carbide tools by CNC milling. We have put this blog post together to illustrate the differences between horizontal and vertical carbide milling and can help you decide which one is best for you.

Vertical Milling Machine

In this type of machine, the spindle axis is set vertically. The foundation of verticle milling machines is made out of 100% cast iron which offers higher compressive fortitude. The screw jack is attached to the cast iron base and functions in a vertical direction. Due to the vertical alignment, the one downside of vertical milling is that it has lower efficiency, but it is more commonly used among industries.

Main Factors of Vertical Milling Machines

- These machines tend to be more affordable and therefore more widely used. Many CNC companies use this type of cutting.

- These machines require a smaller area

- Lighter in weight

- Highly versatile

Horizontal Milling Machine

A horizontal milling machine differs by having the spindle axis set in a horizontal direction and the screw jack operates at the same orientation. There is both an arbor and a spindle. The arbor is an extension and fits within the spindle. This extra part of horizontal milling machines transfers the rotational spin to the cutter, producing a fantastic finishing. It also allows the cutting chips to be removed more easily.

Main Factors of Horizontal Milling Machines

- This type of machine is more expensive

- Allows for optimal surface finishing

- This type of milling produces maximum tool life

- Can effortlessly do the work of 3-4 milling machines and has a higher productivity

- It has more strength, power, and a heavier weight

Both vertical and horizontal milling machines are used in the manufacturing industries. Each system has its own unique advantages and downsides. Whether you are looking for more quantity or quality, more longevity, or a more affordable option, we hope this blog post will help you find out what CNC machine is better for you.

The Epic Tool team is dedicated to providing our clients with exceptional carbide cutting tools. Contact our office in Stoney Creek today for more information on custom carbide tools and our manufacturing approach. We look forward to hearing from you!