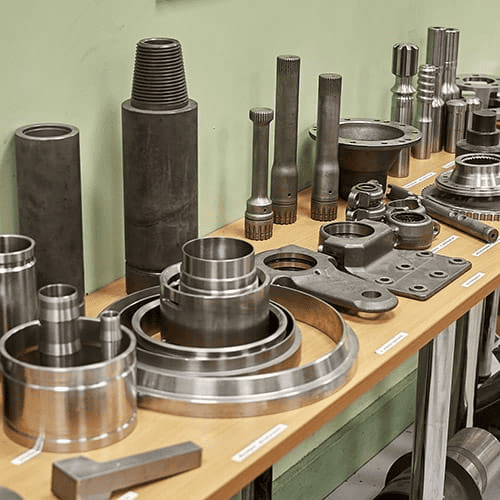

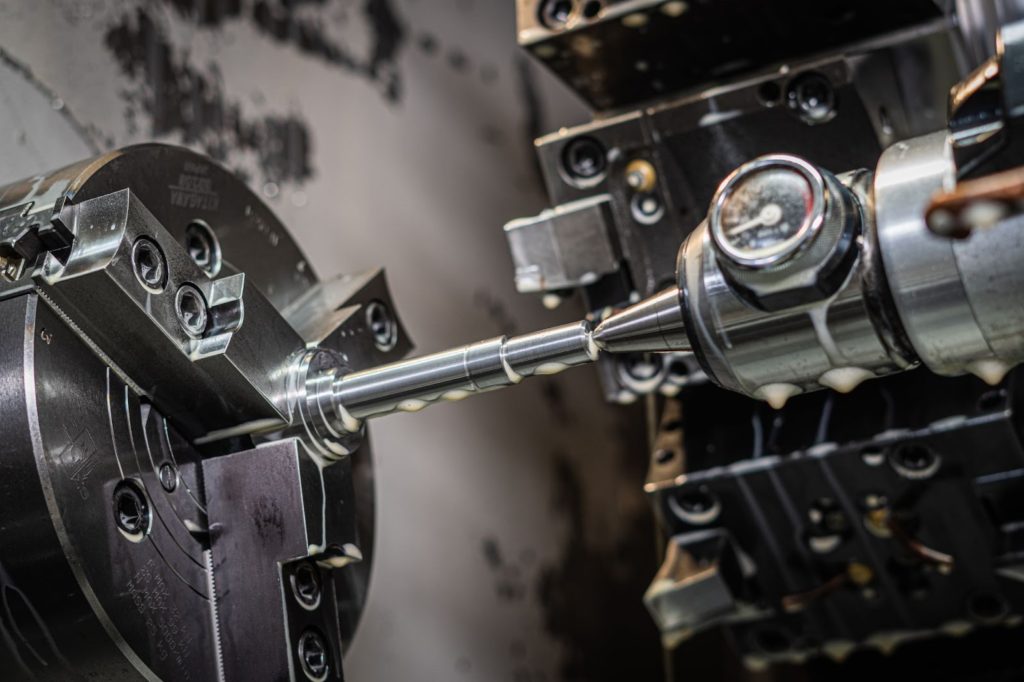

In the world of aviation, precision is not just a luxury; it’s a necessity. Every component of an aircraft, from the smallest screw to the largest wing, must meet rigorous standards to ensure safety and reliability. One key player in this high-stakes game is carbide-cutting tools. These remarkable tools play a pivotal role in […]

Read More… from Precision in the Skies: The Role of Carbide Cutting Tools in Aircraft Manufacture