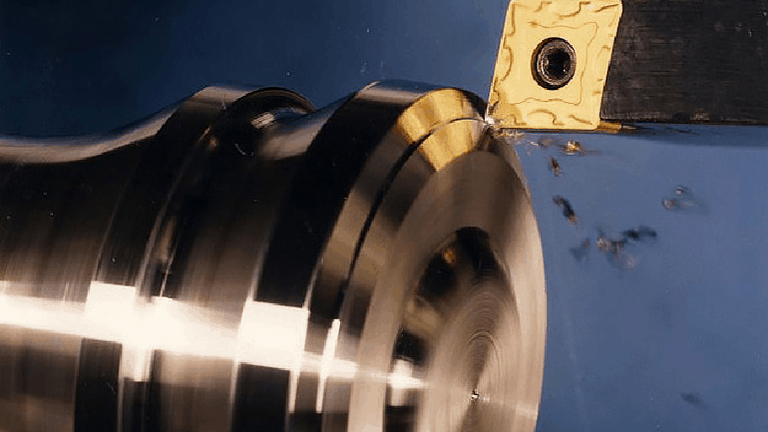

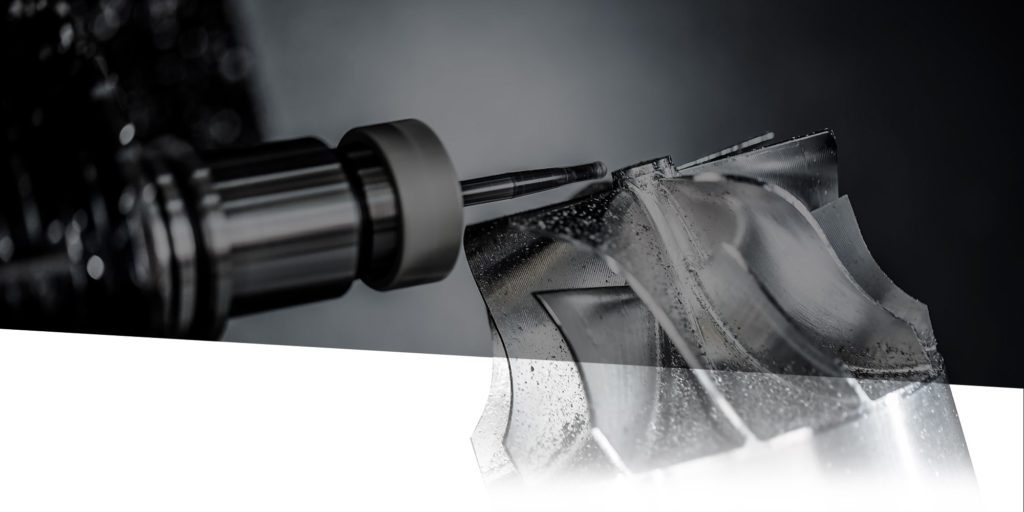

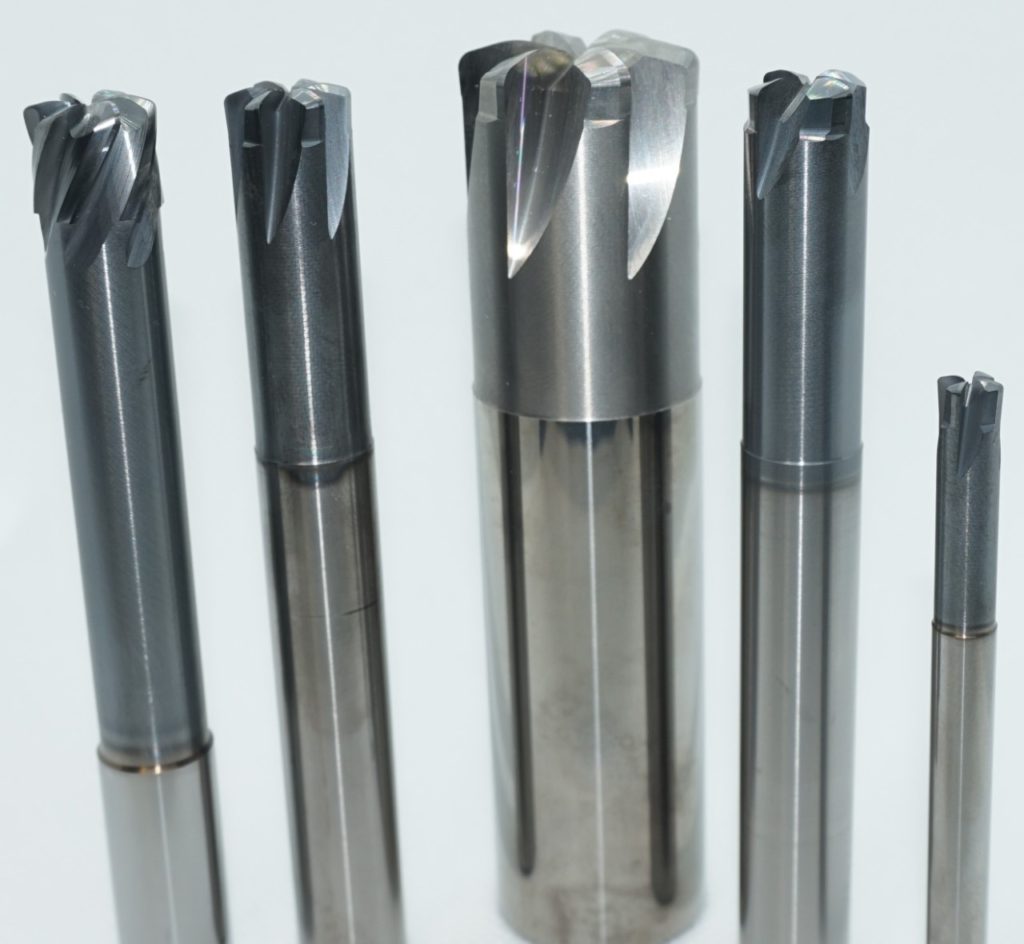

Heat is a natural byproduct with any cutting tool application, but it’s important that you know how to minimize it, as it will improve the life of your tool. Heat isn’t always bad and doesn’t need to totally be avoided, although, controlling heat will help prolong your tool life. Taking every precaution possible to redirect […]

Read More… from Reducing Heat Generation in Cutting Tool Applications