Millstar Profile Milling Tools represent the latest advances in both profile and contour milling technology. Millstar allows customers to see greater results such as shorter machining and lead times and higher machining accuracy.

Customers of Millstar include die and mold machining companies, aluminum extrusion companies, high speed machining mold makers and companies from the aerospace and medical component industries.

The Inserts

Millstar inserts are fully ground precision inserts for better chip control, faster metal removal and higher surface accuracies. They are far more accurate than pressed and O.D. sharpened inserts. Positive ground chipbreaker or strong negative cutting edge designs guarantee outstanding cutting performance in a wide variety of ferrous and non-ferrous materials.

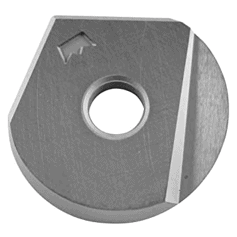

MBT SuperFinisher – Ball Nose Insert

Precision ground, harder grade, for semi-finish and finish milling. Excellent choice for unattended finish milling at small depth and high speeds and feed rates.

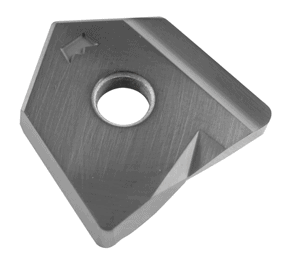

BDS Flat Bottom Insert

Precision ground, non chipbreaker. Unique crossover design between flat bottom and back draft inserts. Allows straight walls with a larger step down than BD, but less cutting forces than FB; allows higher cutting speeds and feed

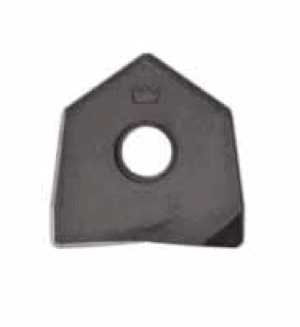

Small Ball Nose & Back Draft Inserts

Used for semi and finish-milling small radius or detail work, and surface milling in soft and hard steel, cast iron, aerospace and non-ferrous alloys, graphite, etc. Suitable for high speed and hard milling.

BD-R Backdraft Insert

Precision ground, with positive ground chipbreaker and 7 degree backtaper. Used for milling of cores, cavities, fillets with straight or very steep walls of softer material.

High Feed Inserts

Millstar HF insert is designed for High feed and High speed machining. It runs at high cutting speed and feed rates with shallow depth of cut. It allows the chip to flow up and out of the cut quickly. It allows heavy chip loads.

MillSTAR Coatings

NA

Non-coated grade.

XRN

Multi-layer hybrid coating of AlCrN. This coating has very good heat resistance and also a low friction coefficient. The XRN coating is designed for use in HSM of un-heat treated softer materials such as Titanium, Inconel, Stainless Steels and other gummy materials that require the use of liquid coolant.

HSN

Millstar’s new coating is a multi-layer hybrid Nano coating. This new coating has very good heat resistance and high hardness. The HSN coating is designed for use in HSM of Heat Treated materials up to 72 HRc.

ALTiN-EXALON (TLN)

Titanium Aluminum Nitride advanced PVD coating. A special, improved ALTiN

coating approaching surface hardness of CBN on a tough substrate. Recommended

for tough and hard metal machining applications.

DMD

Diamond coating. Custom coating for cutting nonferrous, non-metallic and very abrasive materials at highly elevated speeds. Use on copper, bronze, brass, aluminum-silicon alloys, carbon graphite, solid and fiber-reinforced plastics, ceramics and composite materials.

Epic Tool has been the major Canadian importer and warehouse for both Millstar USA and exclusively Millstar Canada for many years now. You can contact us for any inquiries, or questions by phone or email using the contact information given on our website.