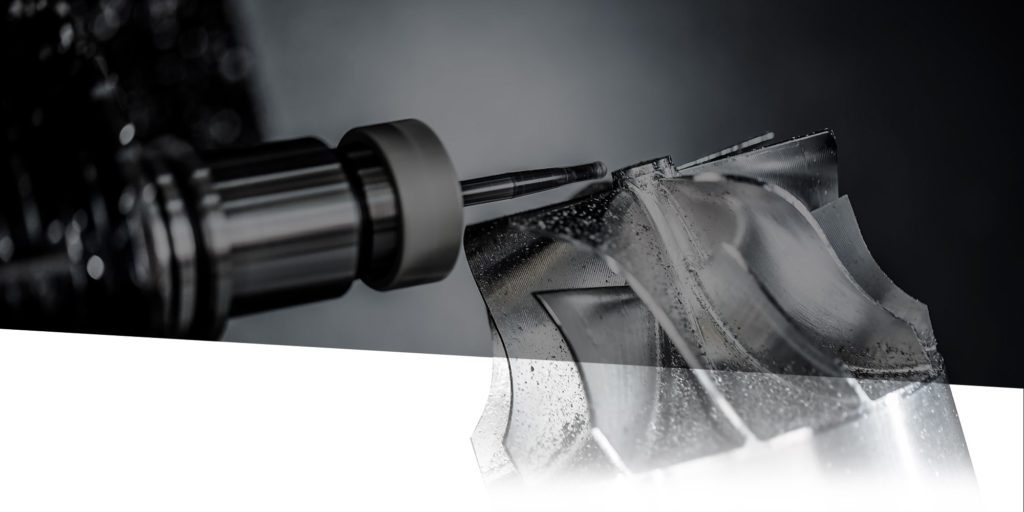

The Team here at Epic Tool in Stoney Creek, Ontario, is proud to work with one of the most robust and most widely used materials, Carbide, on a daily basis since 2005. From CNC milling to custom carbide tool cuts, we are not only happy but proud to use this material in our everyday life, […]

Read More… from Why Carbide Remains One of the Most Popular Tool Materials