What is the Difference Between Mold and Die?

A DIE IS a block of metal with a special shape or with a pattern cut into it that is used for shaping other pieces of metal such as coins or for making patterns

A MOLD (or mould) is a container that you pour liquid metals or substance into which then becomes solid in the same shape as the container when it is cooled or cooked.

Molds tend to be used to produce products that need to be hollow in the middle, whereas dies are used to stamp solid products out of media such as steel.

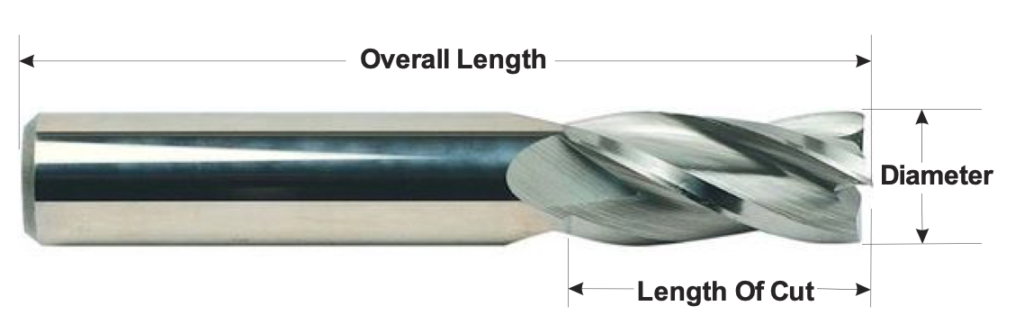

Cutting Tools

Cutting tools come in a range of sizes, materials, and geometry types. In end milling, the cutter generally rotates on an axis vertical to the workpiece. Cutting teeth are located on both the end face of the cutter and the periphery of the cutter body.

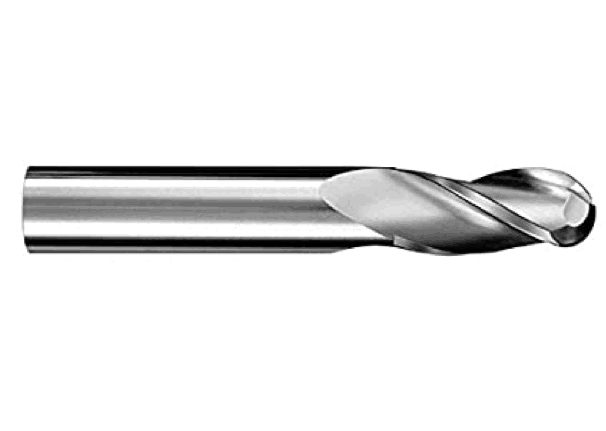

Ball End Mills

A ball end milling cutter is also known as a “ball nose mill”. The end of this tool is ground with a full radius equal to half of the tool diameter, and the edges are center cutting. They can be single end or double end and they can be made from solid carbide or various compositions of high-speed steel.

Use: They can be general purpose or high-performance geometries. They can be used for milling a large corner radius, grooving with a full radius, and contour or profile milling. The smaller diameters can be used for engraving.

Roughing End Mills

Fine tooth roughing end mills remove less material, but the pressure is distributed over many more teeth, for longer tool life and a smoother finish on high temperature alloys and stainless steel.

Use: roughing end mills are designed to remove large amounts of metal quickly and more efficiently than standard end mills. Coarse tooth roughing end mills remove large chips for heavy cuts, deep slotting and rapid stock removal on low to medium carbon steel and alloy steel prior to a finishing application.

2-Flute Finishing End Mills

Finishing End Mills are designed for machining a V-shaped slot in one pass, as well as milling notches, chamfers, serrations, and angles. A wide range of coatings such as Titanium Carbon Nitride (TiCN), and Diamond finishes permit maximum performance and value for a particular application or material.

Use: used in metalworking applications for removing material or burrs from a workpiece and leaving behind a smooth finish. 2-Flute Finishing End Mills are used for center cutting (plunge cut) operation and when chip removal in slots & grooves is a problem.

Miniature End Mills

Miniature Single End Mills are small diameter milling tools which provide rigidity and increased performance when doing short, precise cuts. Recommended for small parts and difficult to machine materials.

Use: miniature end mills are used in the aerospace, medical, optical & electronics industries. The 2 Flute design has better chip removal, while the 4 flute design provides a finer finish and longer tool life.