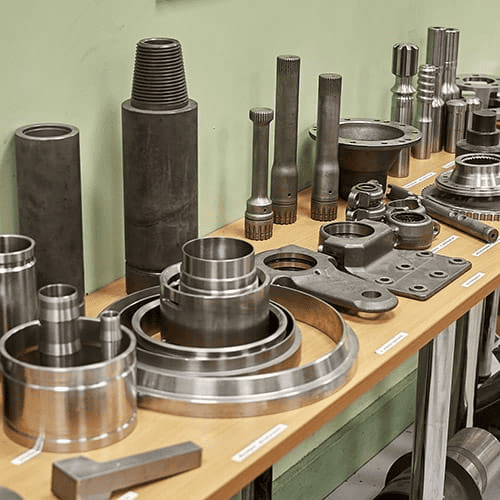

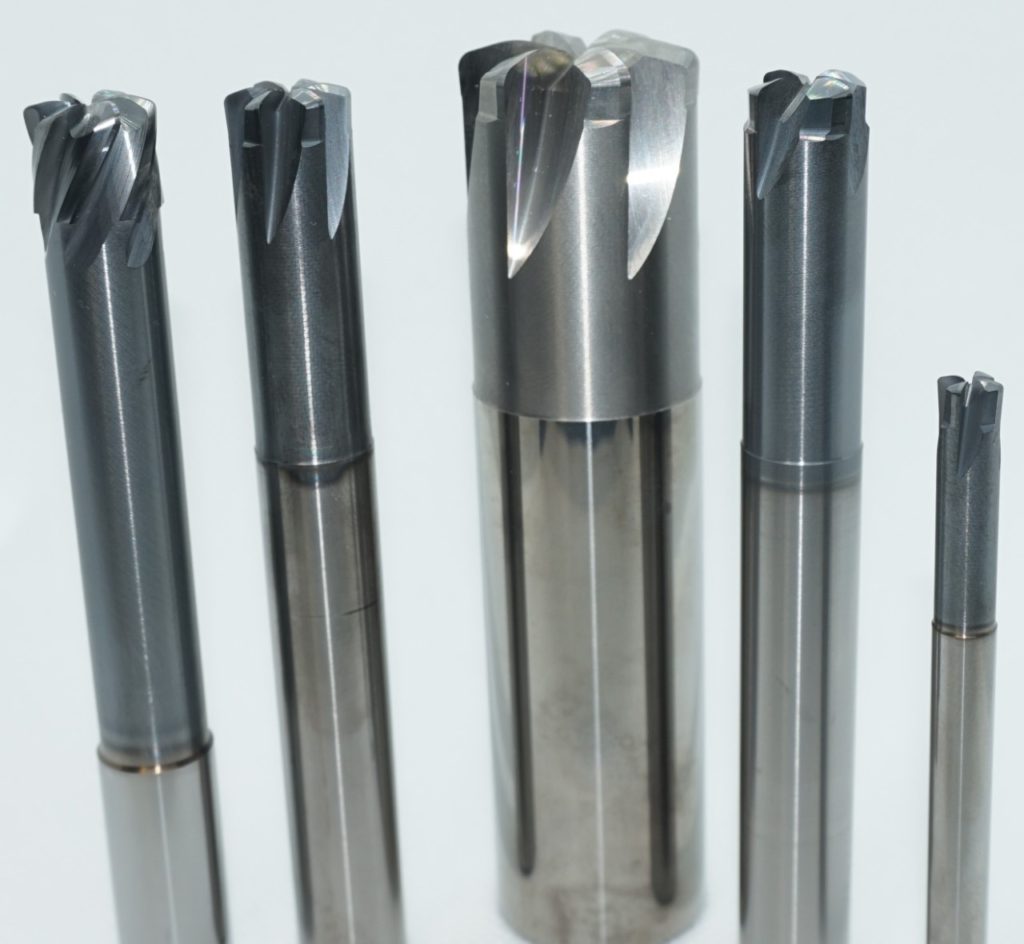

The world of mold and die making is a precise and demanding field where every cut and contour matters. Achieving the desired precision and surface finish is paramount to creating high-quality molds and dies for various industries, from automotive to aerospace. One of the crucial decisions mold and die makers face is choosing the right […]

Ball Nose Tools vs. High Feed Solid Carbide End-Mills in the Mold and Die Making Industry