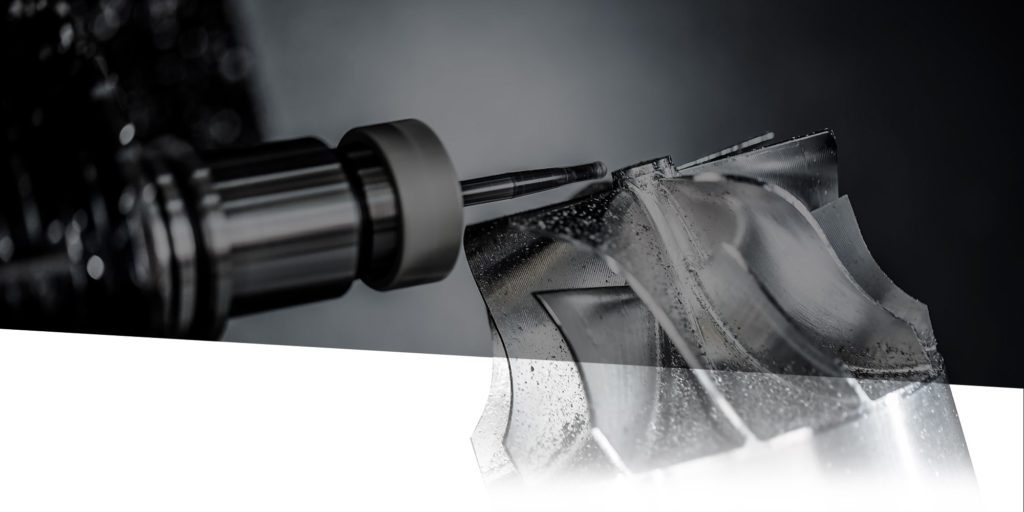

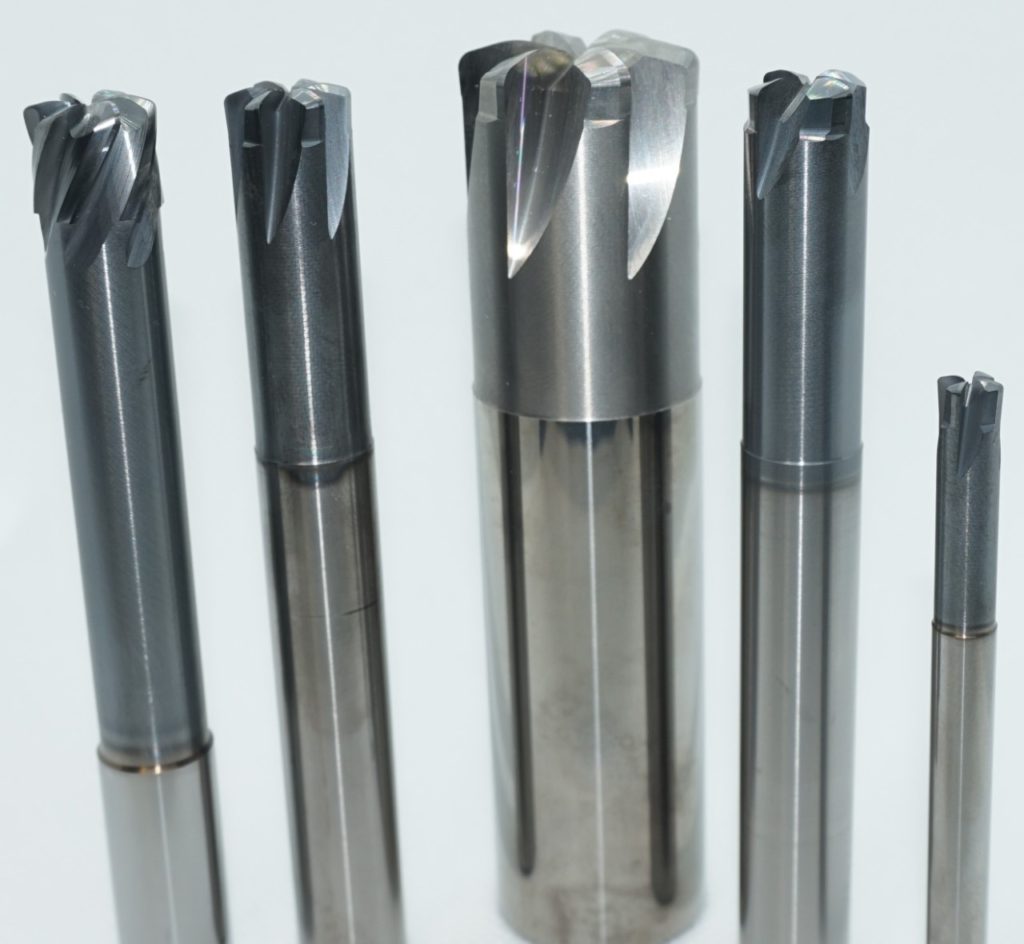

Unnecessary Machining A common mistake when designing parts is designing unnecessary features to machine. Such unnecessary machining adds to your run time and final production cost. There are many approaches that may be a neat addition to your machine visually, but add significant run time to machine away the remaining material. Instead, eliminate the need […]

5 Mistakes to Avoid When Designing Parts