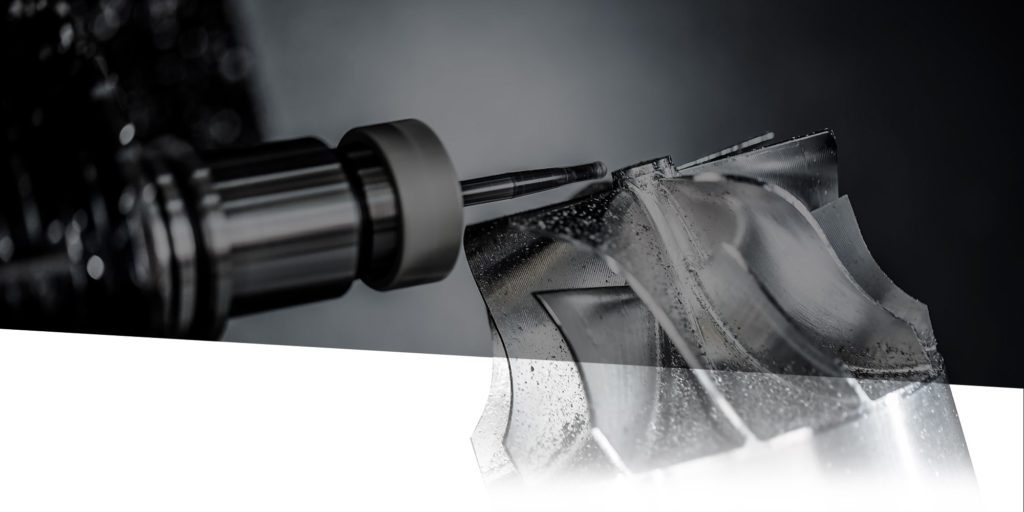

It is not uncommon for machining centres to have automatic tool changing devices to automate the tool changing process. Newer models exhibit quicker tool changing times. If you’re trying to minimize cycle time, there may be some things you can do to reduce tool change time. Reducing tool changing time will make the machine more […]

Speeding Up Your Tool Change Time