What is Ballbar Testing?

Ballbar Testing – the easiest, fastest, and most precise method for determining the accuracy of CNC machine cuts. With the advancement of technology surrounding CNC machines and their maintenance, the use of Ballbar Testing has become a standard operating procedure for a lot of production floors, including the one at Epic Tool. Ballbar testing distinguishes benchmarks and assists operators with tracking the performance of their machine. This allows the operator to assess the performance results, ultimately determining if any operation issues arise. By diagnosing problems early on, CNC operators can easily tweak components and continue with production rather than shutting down the CNC machine entirely for repair or replacement.

How does Ballbar testing improve machining?

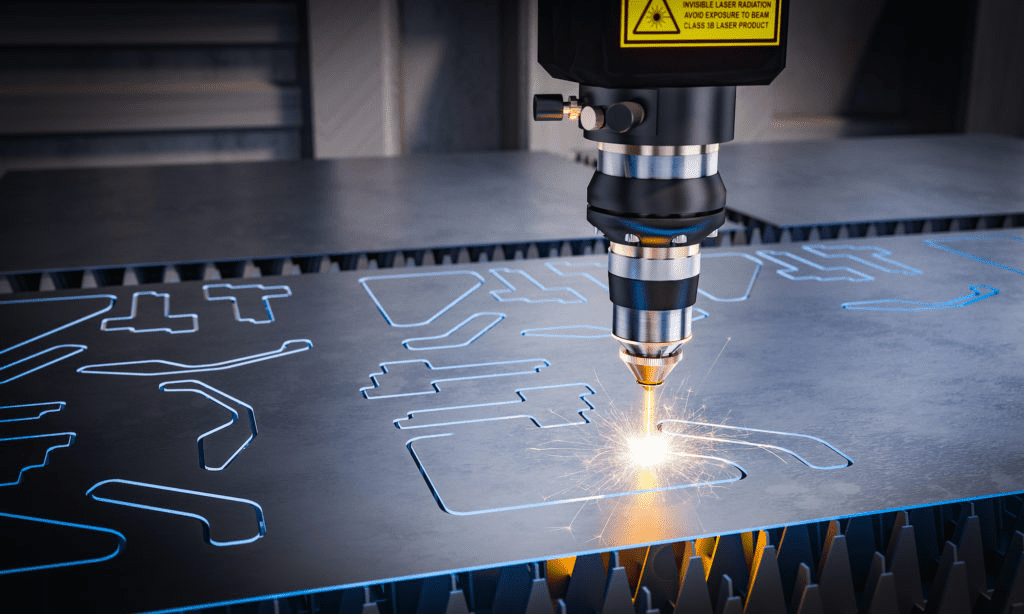

In simple terms, Ballbar Testing uses a measurement tool that determines the accuracy of a CNC tool while it’s in use. By attaching a Ballbar Testing tool to a CNC machine, an operator can quickly assess how smooth the machine is executing perfect circular movements and other types of cutting designs according to specifications set by the operator. If the CNC machine is performing optimally, patterns drawn by the tool will perfectly match the specified dimensions for its cuts. If there are any inconsistencies in the design pattern, the tool will show errors in the CNC machine’s functionality.

Can I have technicians perform Ballbar tests for me?

They most certainly can. Most CNC machinery distributors, dealers, and service support offer Ballbar Testing tool kits, as well as performance tests for customers. In comparison to the time and cost needed to conduct a production back to perfect standards versus the cost to dispose of workpieces and start over, Ballbar testing will save you a lot of time, money, and hassle.

Here at Epic Tool, our CNC operators perform Ballbar Testing routinely to guarantee correct CNC machine performance. It’s important we utilize it because failure to do so will result in extra costs like tool failures or machine breakdowns.

Ballbar testing can prevent costly mistakes

Ballbar Testing is an important tool in any CNC operator’s toolbox. CNC machinery manufacturers, distributors, and dealers are very familiar with the technology, its advantages, and its applications. All it takes is a phone call and you’re on your way to improved CNC machine capacity, lower production costs, and less machine downtime due to inaccuracy. With the introduction of Ballbar Testing into CNC machine maintenance protocols, manufacturers, production floors, and machine shops will quickly increase productivity, customer satisfaction, and overall production cycles.

Looking for a reliable tooling solutions company that can design and manufacture your product? Then you’re in the right place. Contact us today!