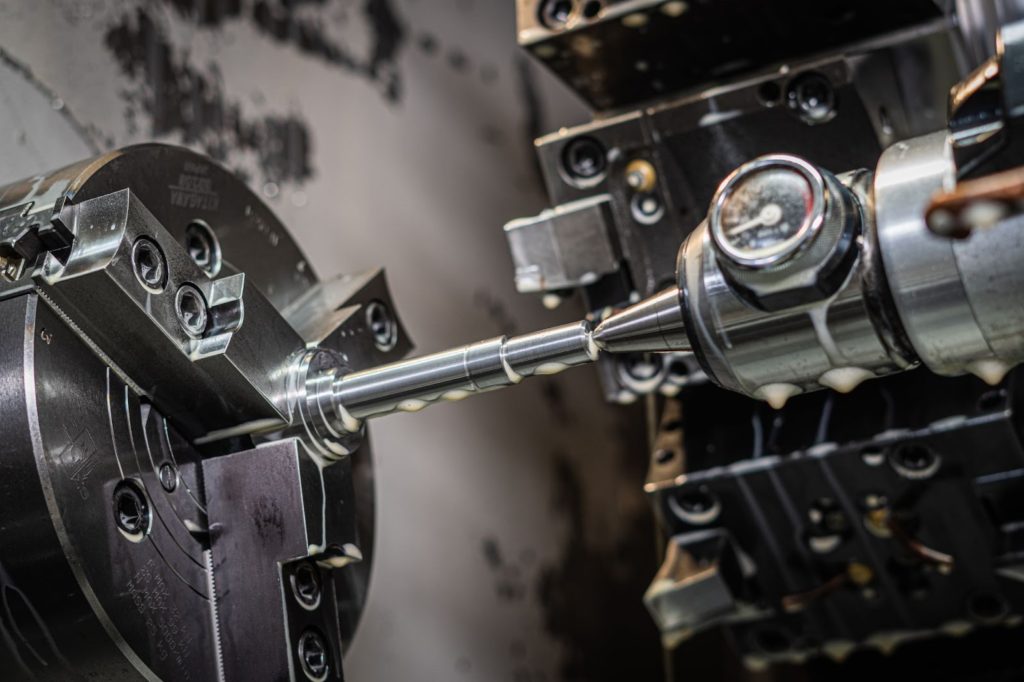

In the fast-paced world of the automotive industry, precision and efficiency are paramount. To meet these demands, the industry relies heavily on advanced manufacturing techniques and cutting-edge tools. Among these tools, carbide cutting tools have emerged as an invaluable asset. Combining durability, versatility, and high-performance characteristics, carbide cutting tools have revolutionized the way automotive components […]

Read More… from Unleashing the Power of Carbide Cutting Tools in the Automotive Industry