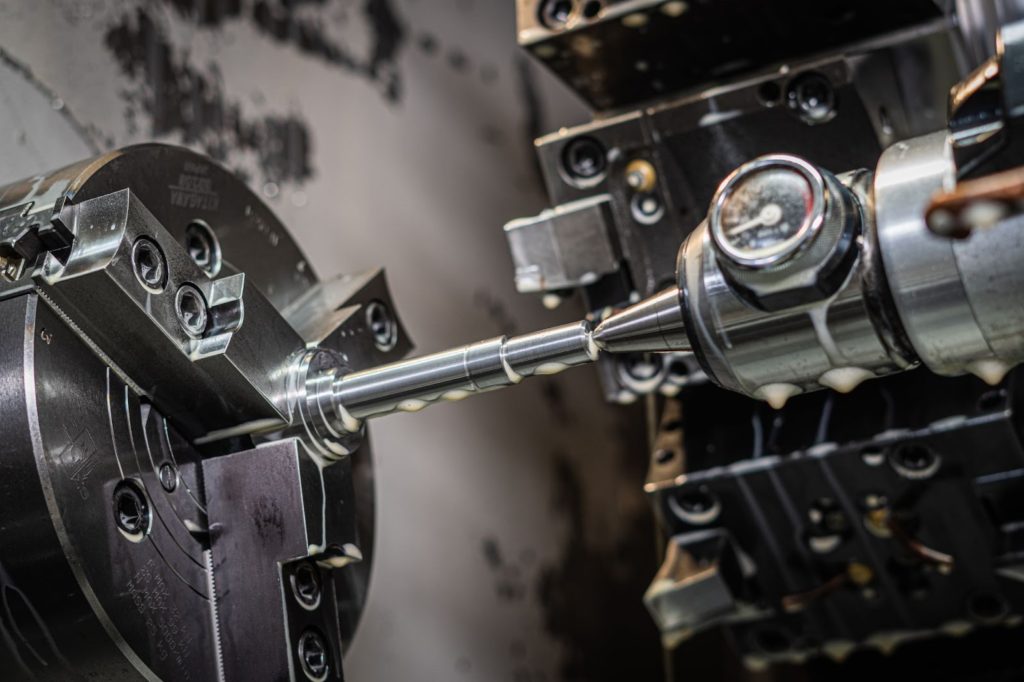

The CNC (computer numerical control) machining industry is constantly advancing, and in 2023, we can expect to see even more advancements that will shape the future of manufacturing. Here are five ways that the CNC machining industry is advancing in 2023:

Increased Automation

Automation is becoming more and more prevalent in the CNC machining industry, with more machines being equipped with advanced sensors and software that can perform tasks without human intervention. This increased automation allows for more efficient and accurate production, as well as reduced labor costs.

3D Printing Integration

3D printing and CNC machining are becoming increasingly integrated, with many CNC machines now capable of 3D printing in addition to traditional machining operations. This allows for greater flexibility in the production process, as well as the ability to create complex and unique shapes that would be difficult or impossible to produce with traditional machining methods.

Advanced Materials

The CNC machining industry is also advancing in terms of the materials that it can work with. We are seeing more and more CNC machines that are capable of working with advanced materials such as carbon fiber, ceramic matrix composites, and other high-performance materials. This allows for the production of stronger, lighter, and more durable parts and components.

Virtual and Augmented Reality

Virtual and augmented reality technology is being increasingly used in the CNC machining industry to provide a more immersive and interactive experience for operators and engineers. This technology can be used for training, programming, and even remote operation of CNC machines.

Internet of Things (IoT) integration

IoT technology is being integrated into CNC machines to allow for real-time monitoring and data collection. This allows for more efficient and accurate production, as well as the ability to predict and prevent potential issues before they occur. This also allows for better tracking of the production process and machine status, which can be used to improve the overall production process.

Shaping The Future

Overall, we can see that the CNC machining industry is advancing rapidly in the areas of automation, advanced materials, virtual and augmented reality, and IoT integration. These advancements will help to improve the efficiency, accuracy, and flexibility of the production process, and will shape the future of manufacturing. With these advancements, CNC machining will play a bigger role in shaping the future of manufacturing technology.

As the future of CNC machining continues to advance, so do our practices here at Epic Tool. We’re dedicated to providing our customers with the highest quality carbide cutting tools. Contact us today for more information.