The team here at Epic Tool is a dedicated carbide tool company specializing in constructing carbide tools for all commercial and specialized manufacturing needs. We have developed excellent relationships with our customers from various trades and industries. We are happy to be a part of innovative industries and technological developments from aerospace, automotive, power generation, and more.

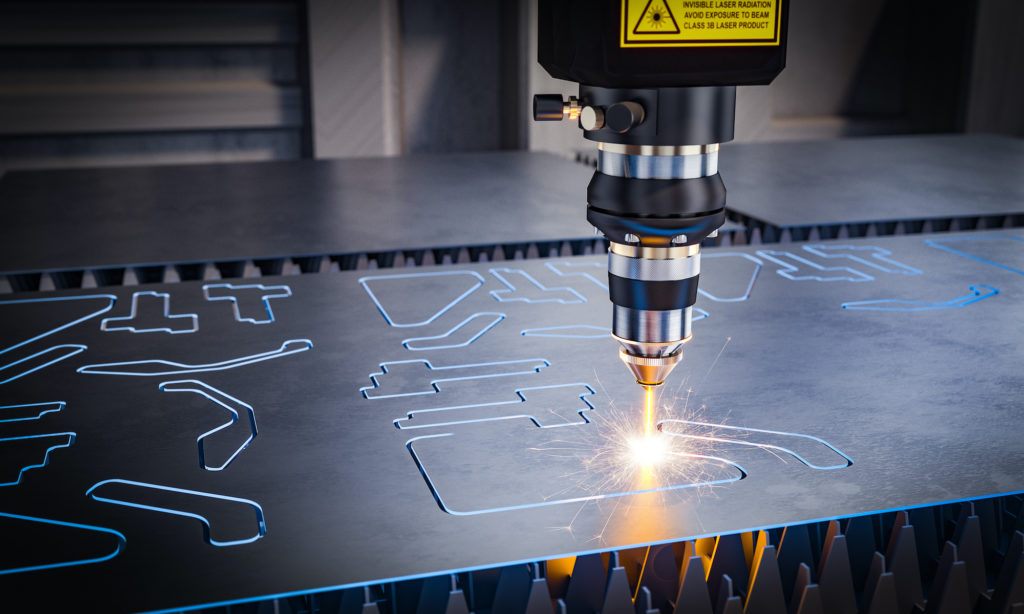

As specializers in Carbide tools through CNC machinery (computer numerical control), we have become well versed with techniques on how to sustain the life space of your CNC machine. Our team has put this blog post together to highlight tips on how to increase your CNC machine longevity.

Know When to Repair

One significant tell-tale sign of damage or need for repair is a change in noise in your CNC cutting. Off noise often results from damaged plating or chips that increase vibrations and higher or lower pitched noise. New chattering noises or sound changes in regular cutting sessions need to be looked into immediately. These signs typically point to a spindle problem. Spindle issues can be more easily resolved than significant and more expensive machine repairs. Being predictive and extra attuned to your machine will help evade significant repairs or replacements.

Have a Go-To Remanufacturing Specialist

If any part of your CNC machine needs repair or inspection, it is well worth it to have a remanufacturing specialist or repairer in your contact beforehand. Our team recommends looking into someone who has experience working and repairing CNC machines before you acquire your new system. Repair specialists will be able to quickly evaluate and give recommendations on the state of your machine. It is great to have someone who keeps a digital photo on record to make sure failure analysis and repair quote reports are accurate. Machine balancing, weighing, and repair are also best left in the hands of experienced technicians using advanced tools and CNC restoration equipment.

Repair and Expect CNC Failure Reports

A failure report is necessary every time a computer numerical control machine has a spindle breakage that leads to a repair. These reports typically include photos and text and details outlining what exactly went wrong. The rebuilder provides this documentation to help owners prevent future breakages or machine failures.

Contact us for any Carbide or CNC Machine Questions

To help ensure minimum downtime, repair costs, and damage to your CNC machine, follow this guide or reach out to our company, Epic Tool, with any questions today!