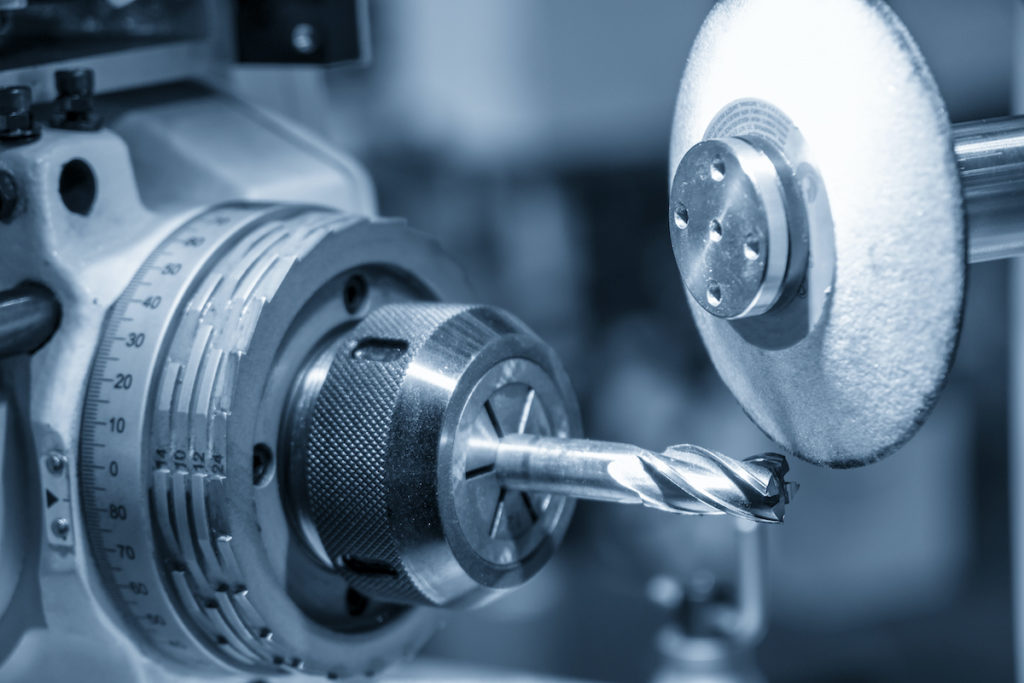

Epic Tool is one of North America’s top carbide tooling solutions companies. We have exclusively worked with carbide for the last ten years and produce upwards of 300 carbide tools per day. You can say we are carbide experts and have outlined the benefits of working with and purchasing carbide tooling solutions for your company.

Test of Time

We work with high-regarded industries such as automotive and aerospace manufacturers; this means our tools produce products that are made to last the test of time. Tough, high-quality tools have high-quality and long-lasting products. Carbide itself is a durable material and therefore can help produce a multitude of products.

Strength

If you don’t already know, carbide is one of the toughest materials out there — it ranks 9 to 9.5 on the Mohs scale. Tungsten Carbide is a heavy solution and almost twice as dense as steel. This results in impressive tooling strength and is an excellent option for tool bits and solutions.

Less Down Time

When you use carbide, you can make more cuts, produce more and result in less downtime. The cutting speed of carbide is almost eight times faster than regular steel. Combining its strength, durability and sharpness, you can cut at a quick and consistent pace without needing to change over the tool, replace it or need it to cool down. This is an important aspect when deciding to work with carbide, as intensive industries in manufacturing need to maintain production numbers. Therefore, carbide is an excellent choice to keep production rates high.

Cleaner Cuts and Finishes

Carbide stays sharp longer. Instead of working with a typical steel tool bit that will need replacement or reworking after a certain amount of cuts, carbide remains intact. This results in on-spec product results, and you won’t need to spend more time or money throwing out products that are not cut effectively or replacing your tool bits more often.

Cost-Effective

Our carbide tooling solutions are cost-effective and are an initial investment that will save you tons of money in the long run. Instead of needing to replace tool bits every six months after aggressive production rates, our carbide will look and cut the same as when you first bought it. With proper training, usage and storage, our products will last you years down the line, saving you and your company money!

Choose Epic Tool for All Your Carbide Tooling Solutions

We live and breathe everything carbide, and we work with it because we know it is the best option for our customers and their industries. For all your custom carbide tool orders and solutions, contact our expert team to discuss them today!