In a world increasingly focused on sustainability, it’s essential to examine every industry and its impact on the environment. The manufacturing sector, in particular, has a significant role to play in reducing its ecological footprint. One often-overlooked aspect of this sector is CNC (Computer Numerical Control) machine recycling. Let’s delve into how sustainability in CNC machine recycling can contribute to a greener future.

The Challenge of CNC Machine Waste:

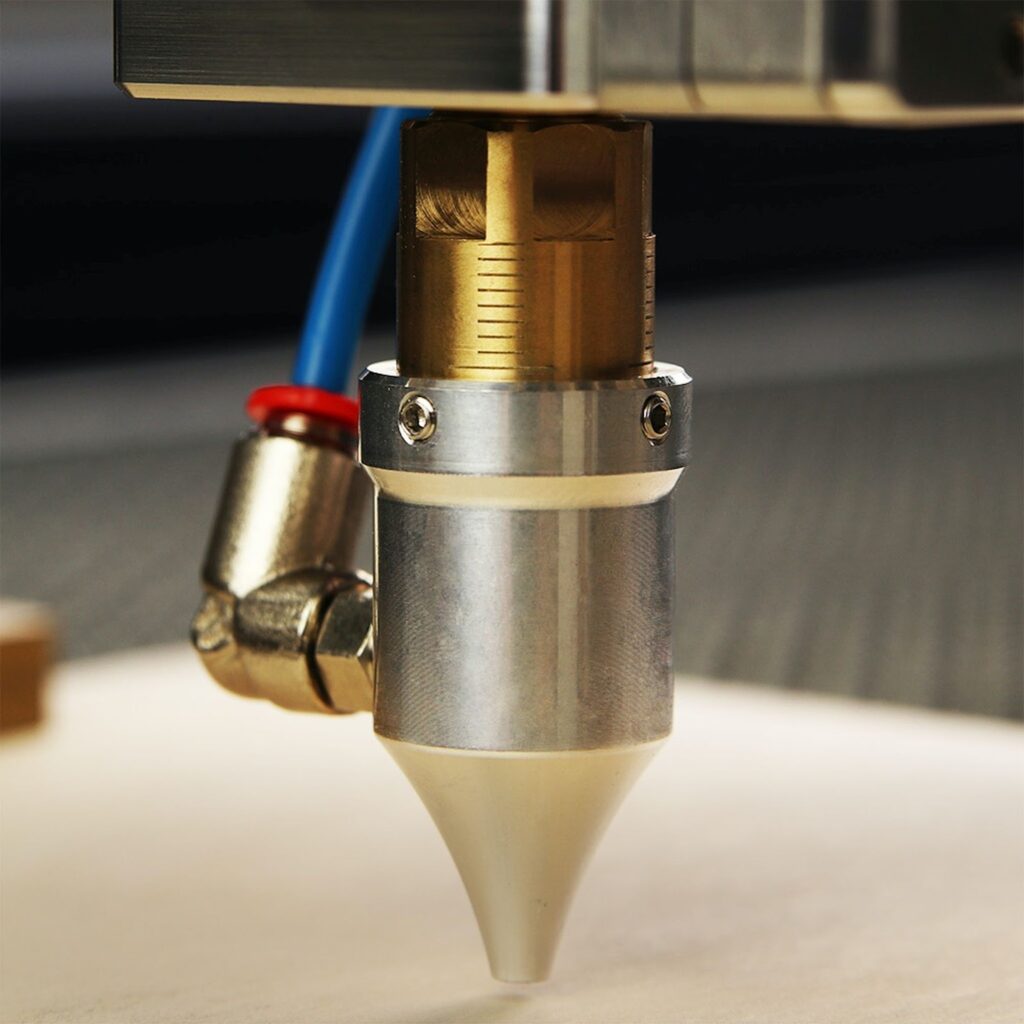

CNC machines are the workhorses of modern manufacturing, precision tools used to shape and mold materials ranging from metal to wood. However, like any machinery, they have a finite lifespan. When these machines become outdated or cease to function efficiently, they are often discarded, contributing to the growing problem of electronic waste, or e-waste. E-waste contains hazardous materials like lead, cadmium, and mercury, which can seep into the soil and water, posing a severe threat to our environment and health.

The Sustainability Imperative:

Sustainability in CNC machine recycling starts with the recognition that these machines contain valuable resources. These resources can be reused, refurbished, or recycled, thus extending the life cycle of the equipment and minimizing the environmental impact.

- Reuse and Refurbishment:

One of the most effective ways to promote sustainability in CNC machine recycling is through the reuse and refurbishment of older machines. Manufacturers can assess the condition of these machines, replace worn-out parts, and upgrade their software to improve performance. By doing so, they not only reduce waste but also extend the useful life of these machines, delaying their eventual journey to the landfill.

- Recycling of Parts and Materials:

When a CNC machine reaches the end of its life, recycling becomes the next best option. Components like motors, enclosures, and circuit boards can be extracted and reprocessed to create new equipment. Metal parts can be melted down and used for other manufacturing purposes. This circular approach reduces the demand for virgin resources and lessens the environmental strain associated with mining and manufacturing.

- Sustainable Manufacturing Practices:

Sustainability doesn’t begin and end with recycling; it must be integrated into the entire manufacturing process. CNC machine manufacturers can adopt eco-friendly production practices, such as using renewable energy, reducing water consumption, and minimizing emissions. These steps can significantly reduce the carbon footprint associated with CNC machine production.

Closing Thoughts:

Sustainability in CNC machine recycling is more than just a buzzword; it’s a critical aspect of modern manufacturing that can positively impact our environment and future generations. By reusing, refurbishing, and recycling CNC machines and adopting sustainable manufacturing practices, Epic Tool reduces waste, conserves resources, and contributes to a greener, more sustainable future. As consumers and manufacturers alike become more conscious of the environmental consequences of their actions, the adoption of sustainable practices in CNC machine recycling has undoubtedly become the new standard for our company. Contact us today for more information!