Introduction

In the world of manufacturing and fabrication, precision and efficiency are paramount. CNC (Computer Numerical Control) technology has revolutionized various aspects of manufacturing processes, including drilling operations. CNC drilling solutions offer manufacturers the ability to achieve consistent, accurate, and high-quality results while optimizing production processes. In this blog, we will delve into the world of CNC drilling solutions, exploring their benefits, applications, and the innovative features that make them an essential tool for modern manufacturing.

The Evolution of Drilling

Traditional drilling methods have come a long way since their inception. Hand-operated drills were followed by machine-based drills, which improved speed and accuracy. However, these methods still relied heavily on manual control, leading to inconsistencies and limitations in achieving complex drilling patterns.

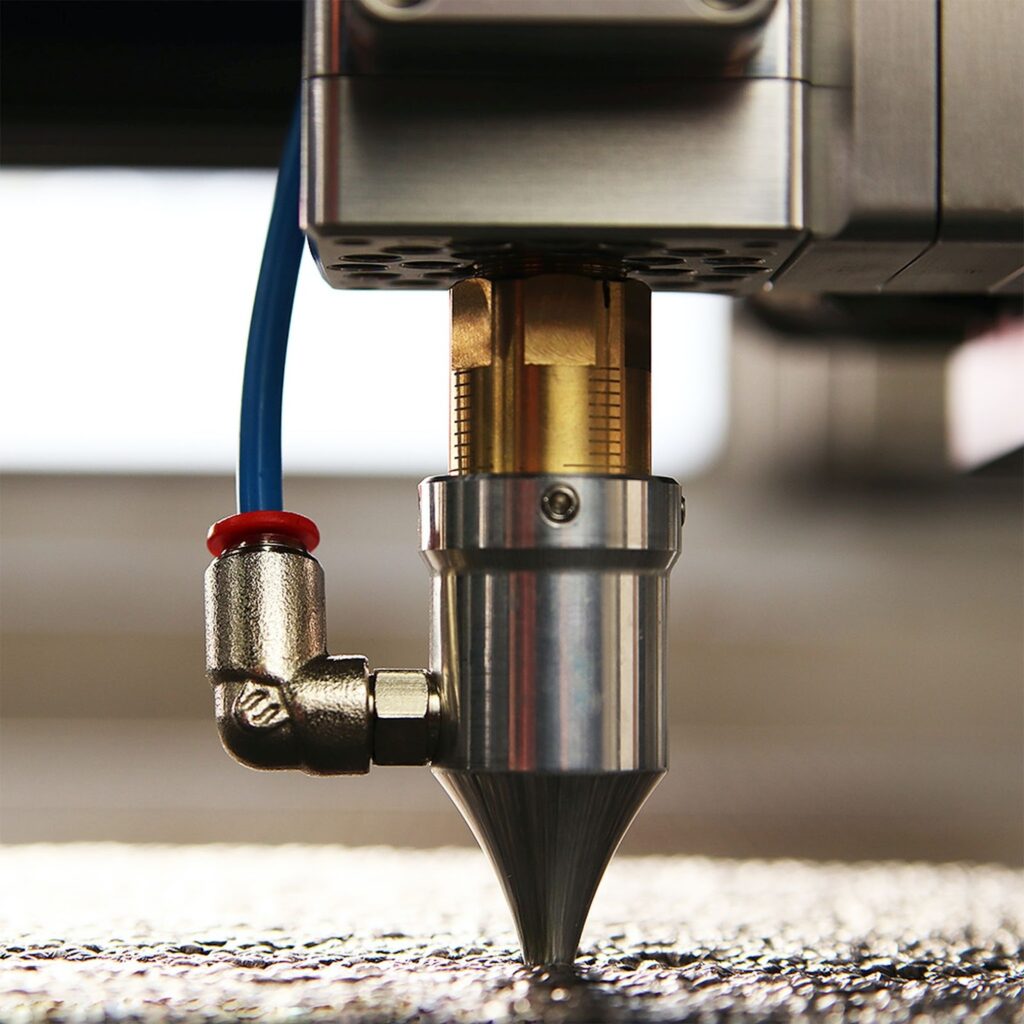

The introduction of CNC technology transformed the drilling landscape. CNC drilling solutions utilize computer programs to control the movement of the drilling machine with exceptional precision. This advancement has opened up new possibilities in various industries, from aerospace and automotive to electronics and medical devices.

Benefits of CNC Drilling Solutions

Precision: CNC drilling solutions are known for their exceptional accuracy. The ability to program drilling paths and depths down to micrometer levels ensures consistent results, reducing material wastage and minimizing the need for rework.

Efficiency: Automated CNC drilling processes significantly enhance production efficiency. The technology can perform repetitive tasks without human intervention, allowing operators to focus on more complex tasks, quality control, and overall process management.

Flexibility: CNC drilling machines can handle a wide range of materials, from metals to composites and plastics. This adaptability makes them suitable for diverse applications, giving manufacturers the flexibility to cater to various industries.

Complex Geometries: Traditional drilling methods often struggle with intricate and complex drilling patterns. CNC drilling solutions can execute these patterns flawlessly, enabling the creation of intricate designs and intricate components.

Reduced Lead Times: Faster drilling speeds and minimal setup times contribute to reduced production lead times. This is especially crucial in industries where time-to-market is a competitive advantage.

Innovative Features

Multi-axis Capability: Many CNC drilling machines are equipped with multiple axes of movement, allowing drilling at various angles and directions. This is particularly beneficial for creating holes in curved or irregular surfaces.

Automated Tool Changes: CNC drilling solutions can be equipped with automatic tool changers that switch between different drill bits or tools without manual intervention. This feature further enhances efficiency and reduces downtime.

Real-time Monitoring: Advanced CNC drilling systems incorporate sensors and monitoring tools that provide real-time feedback on drilling parameters, helping operators detect issues early and make necessary adjustments.

CAD/CAM Integration: Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software can be integrated with CNC drilling systems. This enables seamless translation of design specifications into drilling commands, ensuring accurate results.

Applications of CNC Drilling Solutions

Aerospace: CNC drilling is crucial in aerospace manufacturing, where precision and reliability are paramount. It’s used for creating holes in aircraft components, ensuring secure attachment of parts and maintaining structural integrity.

Automotive: CNC drilling solutions play a vital role in automotive production lines. They are used for drilling holes in engine components, chassis, and body parts with high accuracy and consistency.

Electronics: The electronics industry relies on CNC drilling for creating precise holes in circuit boards and electronic components, ensuring reliable connections and functionality.

Medical Devices: CNC drilling is used in the production of medical implants and devices, where precision is essential to ensure proper fit and functionality.

CNC drilling solutions have revolutionized manufacturing by offering precision, efficiency, and innovation in drilling processes. At Epic Tool, our ability to provide accurate results, handle complex geometries, and enhance overall production efficiency has made us an indispensable tool in various industries. Contact us today to learn more!