2020 has been a year like no other. It would’ve been hard to foresee a global pandemic, a trade war, and a pressing need for employees to work from home. Now we must ask ourselves, what can we assume about the changes 2021 will bring?

Here are a few changes the manufacturing industry will likely see in 2021.

Influence of remote work

Finding qualified workers has been an ongoing challenge within the manufacturing industry, and with the emergence of COVID-19 within the first half of 2020, the challenges only grew as more and more workers were encouraged to work from home.

Now, what manufacturers must ask themselves is how much the emphasis on remote work will influence the day-to-day operations of a manufacturing plant. Will management be able to supervise plant workers adequately without being physically present? How will the continued development of workplace automation impact the push to work from home?

Manufacturing will continue to change and shift as these questions play out in 2021.

Local Instead of Global

There has been a rise of manufacturers shifting their attention to local interests rather than global, and this can be attributed in part to the global pandemic. The rise of tariffs, and the decline of trade due to the coronavirus have all contributed to shifting expectations for industry supply chains.

For example, imports from China have dropped as trade wars and uncertainty lead manufacturers to seek lines of supply. The constantly shifting nature of the web of treaties and trade agreements that regulate imports and exports have caused some industries to prioritize regional markets.

Digitization on the Rise

Digitization promises to continue to radically change manufacturing processes in 2021 and beyond. Manufacturers will face the need to adopt a digital strategy that covers everything from cloud-based data storage to digital marketing.

Internal digitization will include aspects of the electrification allowing better monitoring of infrastructure energy use and fleet energy consumption. External digitization includes adopting digital marketing concepts and emerging B2B2C (Business to business to customer) models.

Companies that embrace digitization – including so-called “born digital” manufacturers that began in the digital age – will find themselves much better-placed to navigate 2021 and beyond.

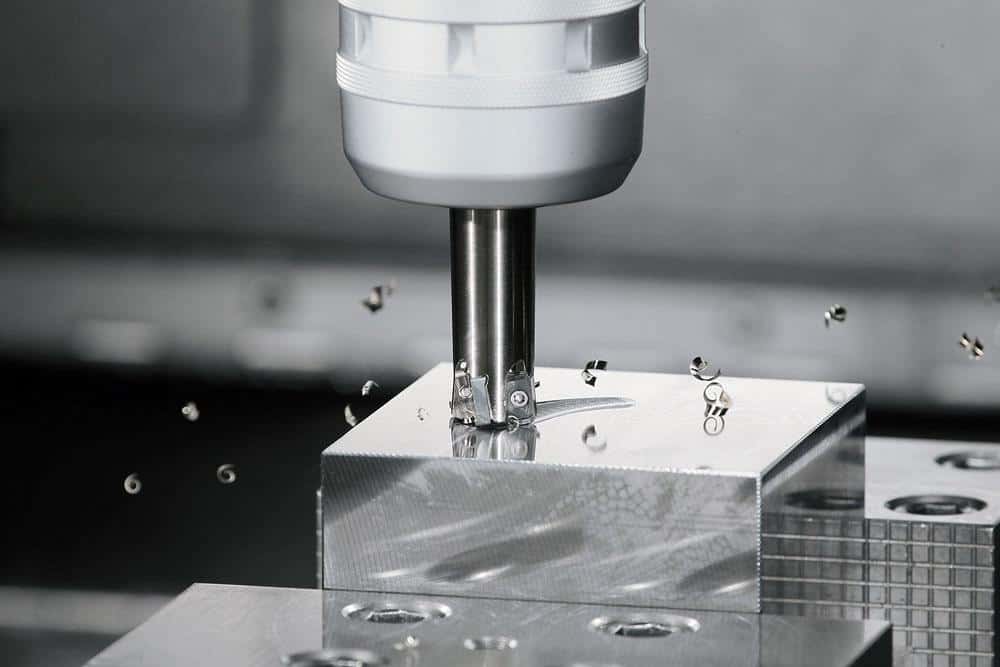

Emerging technology

2021 will see new technologies continue to transform manufacturing. The majority of North American manufacturers have already adopted 3D printing technology in at least a limited role. 3D printing, remote CNC, and other newly-minted manufacturing technologies offer tremendous potential for growth, particularly in combination with each other. 3D printing, an additive manufacturing process, and CNC, a subtractive process, can be used in conjunction with each other to produce and finish components more efficiently.

Automated machinery also holds great promise; while electrification can improve fleet transportation, self-driving vehicles may utterly transform it. And of course, the potential of AI for manufacturing is nearly limitless.

Post-pandemic recovery

2021 holds great promise for a continued, at least partial recovery from the pandemic-influenced economic downturn of 2020. As industries reopen, pent-up demand has led to a quick rebound in some sectors.

Of course, that recovery is not guaranteed to be complete or universal; some sectors, like hospitality and travel, will take years to recover. Manufacturing sectors built around those industries may take a correspondingly long time to rebound. Other factors – like the regional emphasis that will continue to shape manufacturing in 2021 – will lead to increased demand and help boost recovery.